-

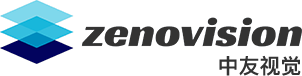

Visual inspection applications for thin filmsDetectionPenetration lighting method for thin film surface

Visual inspection applications for thin filmsDetectionPenetration lighting method for thin film surface

Defects such as missed coating, pinholes (holes), foreign objects, explosions, etc

Continuous capture of various defects, real-time analysis, judgment-

01.

Using standard hardware, low after-sales maintenance costs. Scalable system, facilitating system tra

-

02.

HIS system based on CPU+GPU processing architecture. Fully meet the requirements of high-precision a

-

03.

High brightness and high uniformity light source, with a service life of over 50000 hours

-

04.

A stable and convenient operating system with rich features that support customized development. Adv

-

01.

-

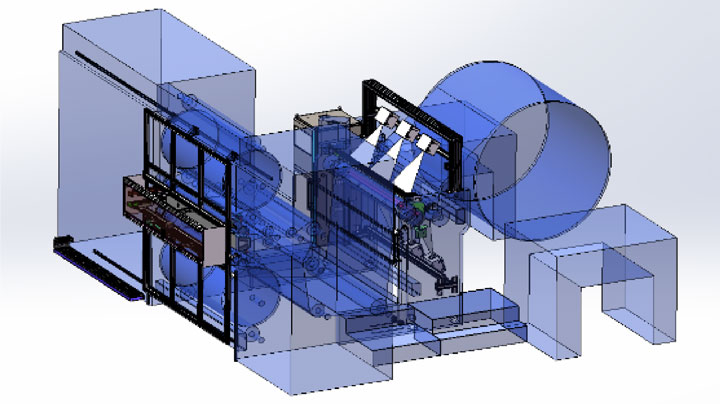

Application of surface defects and pinhole detection in copper/aluminum foilDetectionBased on optical image detection technology

Application of surface defects and pinhole detection in copper/aluminum foilDetectionBased on optical image detection technology

Combining Autonomous Learning Algorithms with Artificial Intelligence

Provide an overall solution for industrial vision-

01.

Using standard hardware, low after-sales maintenance costs. Scalable system, facilitating system tra

-

02.

HIS system based on CPU+GPU processing architecture. Fully meet the requirements of high-precision a

-

03.

High brightness and high uniformity light source, with a service life of over 50000 hours

-

04.

A stable and convenient operating system with rich features that support customized development. Adv

-

01.

-

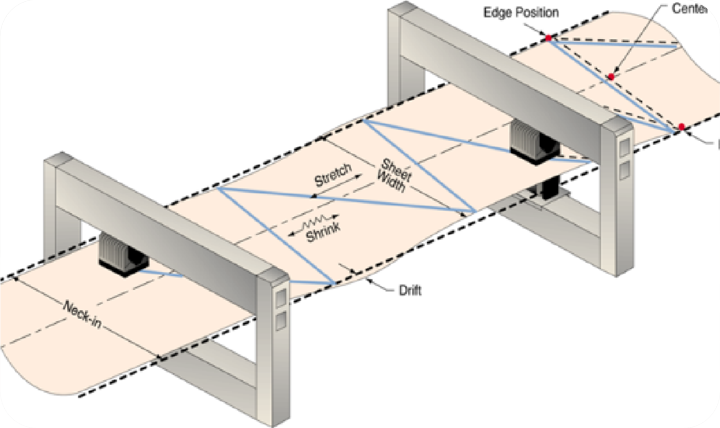

Visual Inspection Application of Plate and Strip MaterialsDetectionBased on optical image detection technology

Visual Inspection Application of Plate and Strip MaterialsDetectionBased on optical image detection technology

Combining Autonomous Learning Algorithms with Artificial Intelligence

Provide an overall solution for industrial vision-

01.

Using standard hardware, low after-sales maintenance costs. Scalable system, facilitating system tra

-

02.

HIS system based on CPU+GPU processing architecture. Fully meet the requirements of high-precision a

-

03.

High brightness and high uniformity light source, with a service life of over 50000 hours

-

04.

A stable and convenient operating system with rich features that support customized development. Adv

-

01.

-

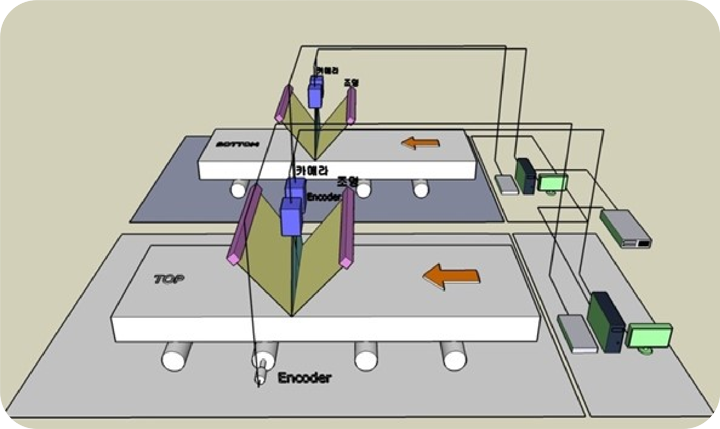

Application of visual inspection on the end face of roll materialsDetectionBased on optical image detection technology

Application of visual inspection on the end face of roll materialsDetectionBased on optical image detection technology

Combining Autonomous Learning Algorithms with Artificial Intelligence

Provide an overall solution for industrial vision-

01.

Using standard hardware, low after-sales maintenance costs. Scalable system, facilitating system tra

-

02.

HIS system based on CPU+GPU processing architecture. Fully meet the requirements of high-precision a

-

03.

High brightness and high uniformity light source, with a service life of over 50000 hours

-

04.

A stable and convenient operating system with rich features that support customized development. Adv

-

01.

-

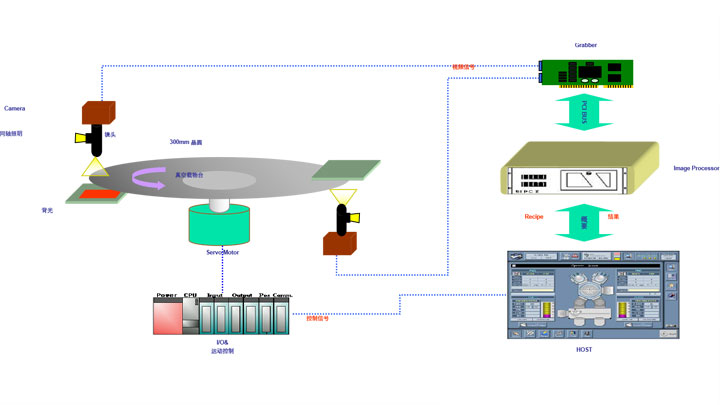

Application of wafer visual inspectionDetectionBased on optical image detection technology

Application of wafer visual inspectionDetectionBased on optical image detection technology

Combining Autonomous Learning Algorithms with Artificial Intelligence

Provide an overall solution for industrial vision-

01.

Using standard hardware, low after-sales maintenance costs. Scalable system, facilitating system tra

-

02.

HIS system based on CPU+GPU processing architecture. Fully meet the requirements of high-precision a

-

03.

High brightness and high uniformity light source, with a service life of over 50000 hours

-

04.

A stable and convenient operating system with rich features that support customized development. Adv

-

01.

-

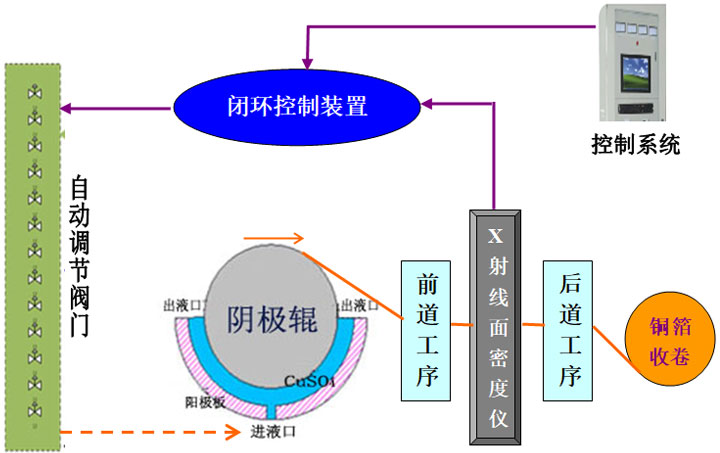

Application of thickness/surface density solutionDetectionBased on X-ray/beta ray/laser technology

Application of thickness/surface density solutionDetectionBased on X-ray/beta ray/laser technology

Assist the factory in quickly entering normal production status

Ensure stable lateral deviation of surface density during daily production process-

01.

Ultra high repeatability X-ray ± 0.05g/㎡, β ray ± 0.08g/㎡, laser ± 0.3 μ m

-

02.

A scientific measurement software system for professional algorithms of ultra-high signal-to-noise r

-

03.

Rich value-added functions. Online measurement, line graph presentation, and data storage. Traceabil

-

04.

X-ray thickness gauge spot, higher stripe resolution. Timely and powerful software customization cap

-

01.

-

Application of automatic adjustment solution for coating die headDetectionCoating thickness 5um-3000um, coating accuracy ≤ 2um

Application of automatic adjustment solution for coating die headDetectionCoating thickness 5um-3000um, coating accuracy ≤ 2um

Adopting PID technology combined with fuzzy control technology to achieve closed-loop control

Realize unmanned operation under normal working condi-

01.

Flexible process control technology, adapted to the process needs of different customers; The modula

-

02.

By setting adjustment intervals and corresponding warning values, better control of product quality

-

03.

Real time monitoring of thickness (surface density) and automatic adjustment of product production l

-

04.

Automatically adjust the thickness (surface density) within the standard range of the product, so th

-

01.